Aim Brake Pressure Sensor 0-160 Bar

Pairs well with

Same Day Shipping

When you order before 15:00 BST

Monday - Friday

Worldwide Shipping

Free Shipping Above £50

All Orders are Carbon-Neutral

Aim Brake Pressure Sensor 0-160 Bar

If you’ve got a question, you’re looking for information, or you just want to chat, please find a host of available help options below.

Brake Pressure Sensor 0-160 Bar

The Aim Brake Pressure Sensor 0-160 Bar is a key tool for racers and engineers who want precise, real time insight into braking performance on track. It’s widely used in both cars and bikes, from club-level to professional motorsport, and can easily be installed in a -3 brake line using a three-way T-piece.

Why Choose the Aim Brake Pressure Sensor

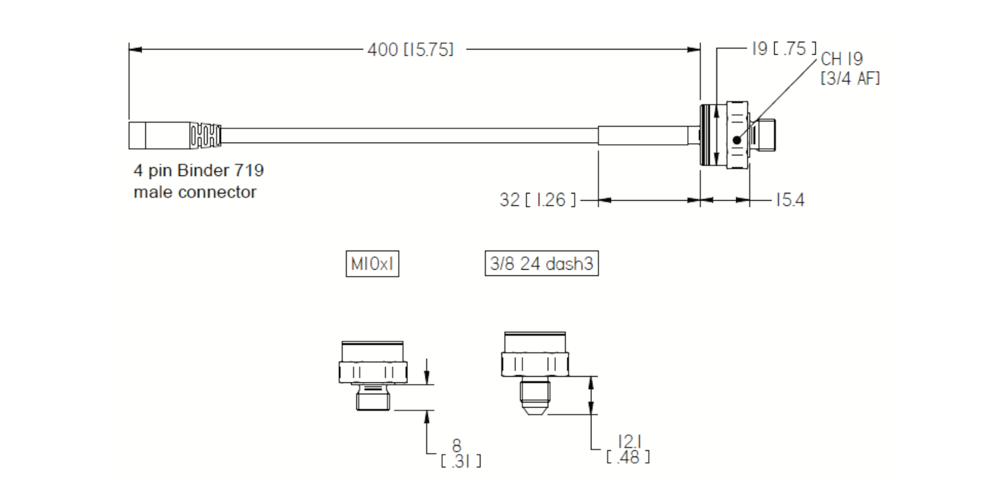

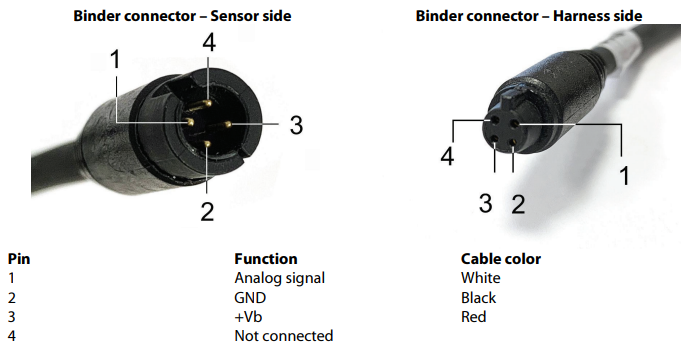

The 0-160 Bar Aim Brake Pressure Sensor is available with -3 JIC (3/8-24 UNF) or M10 thread options and is fitted with a 4-pin 719 male binder connector to suit Aim loggers and dash displays. Whether your car is equipped with single, dual, fixed or adjustable master cylinders, adding brake pressure sensors allows you to monitor brake performance, make real changes and identify issues quickly and precisely.

Driver Feedback: You can see your brake pressure in real time on your display, helping you understand and refine your braking technique, whether you’re trail braking into a corner or modulating pressure to avoid lockup.

Data Analysis: After a session, you can overlay brake pressure data with speed, throttle, and steering inputs. This lets you spot where you’re braking too early, too late, or inconsistently lap to lap.

Setup & Engineering: Engineers use brake pressure data to balance brake bias, tune ABS systems, and diagnose issues like brake fade or air in the lines.

Driver Development: Comparing pressure traces between drivers is a powerful coaching tool, showing exactly how the fastest laps are achieved.

How the Brake Pressure Sensor Works

The Aim Brake Pressure Sensor is installed directly into the hydraulic brake line, usually at a calliper or master cylinder. As you apply the brakes, hydraulic pressure builds up in the line. The sensor detects this pressure and converts it into a voltage signal, which is then sent to your Aim dash or data logger. That voltage is interpreted as a pressure value (up to 160 bar), giving you a live readout of exactly how hard you’re pressing the brakes at any given moment.

0-160 Bar Pressure Sensor

The pressure sensor allows you to detect fluid and air pressures. It offers a high level of reliability and endurance and is protected against the high vibration, shock and high temperatures found in motorsport.

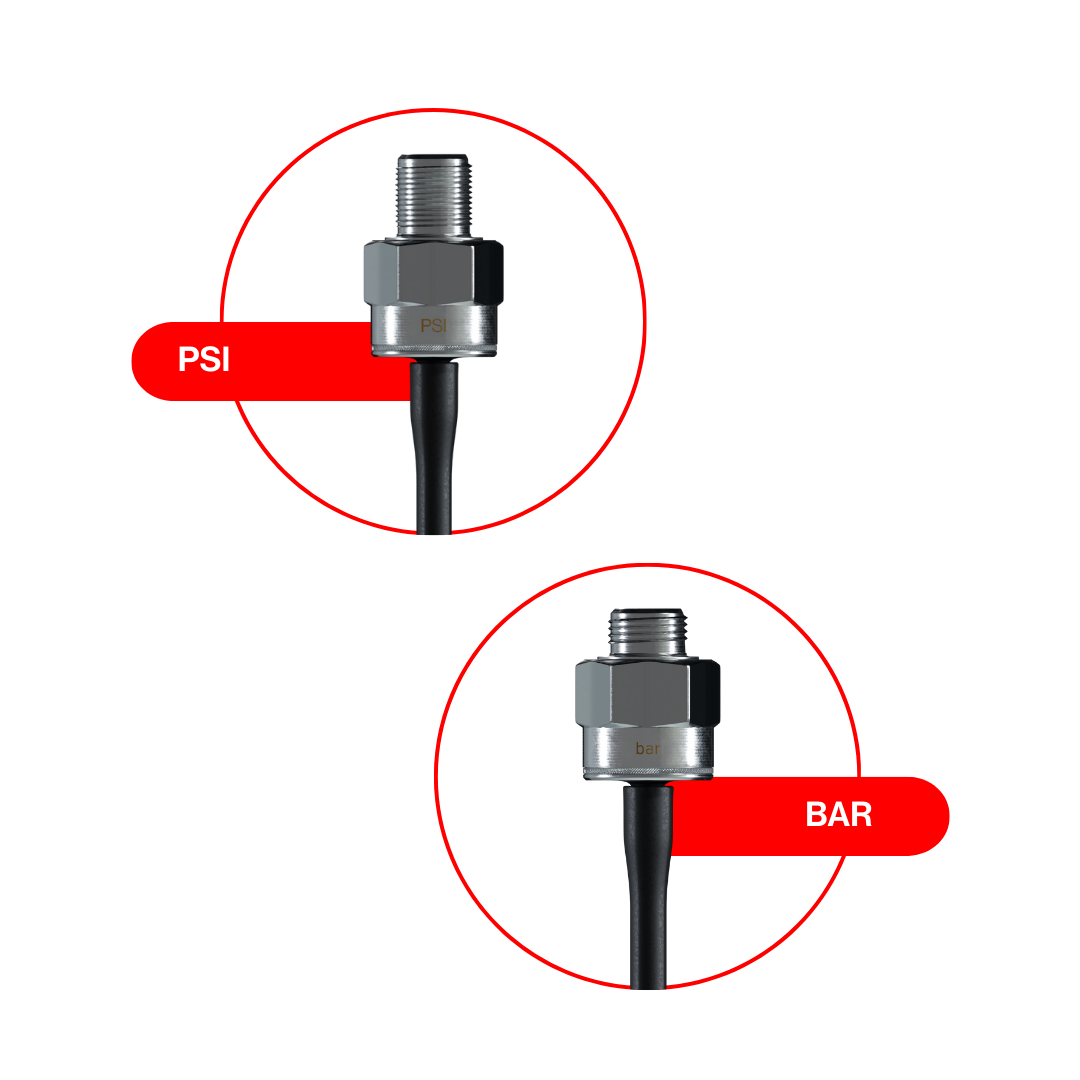

The Brake Pressure Sensor is available with a choice of PSI and Bar variants.

Compatible with MoTeC, Bosch & More

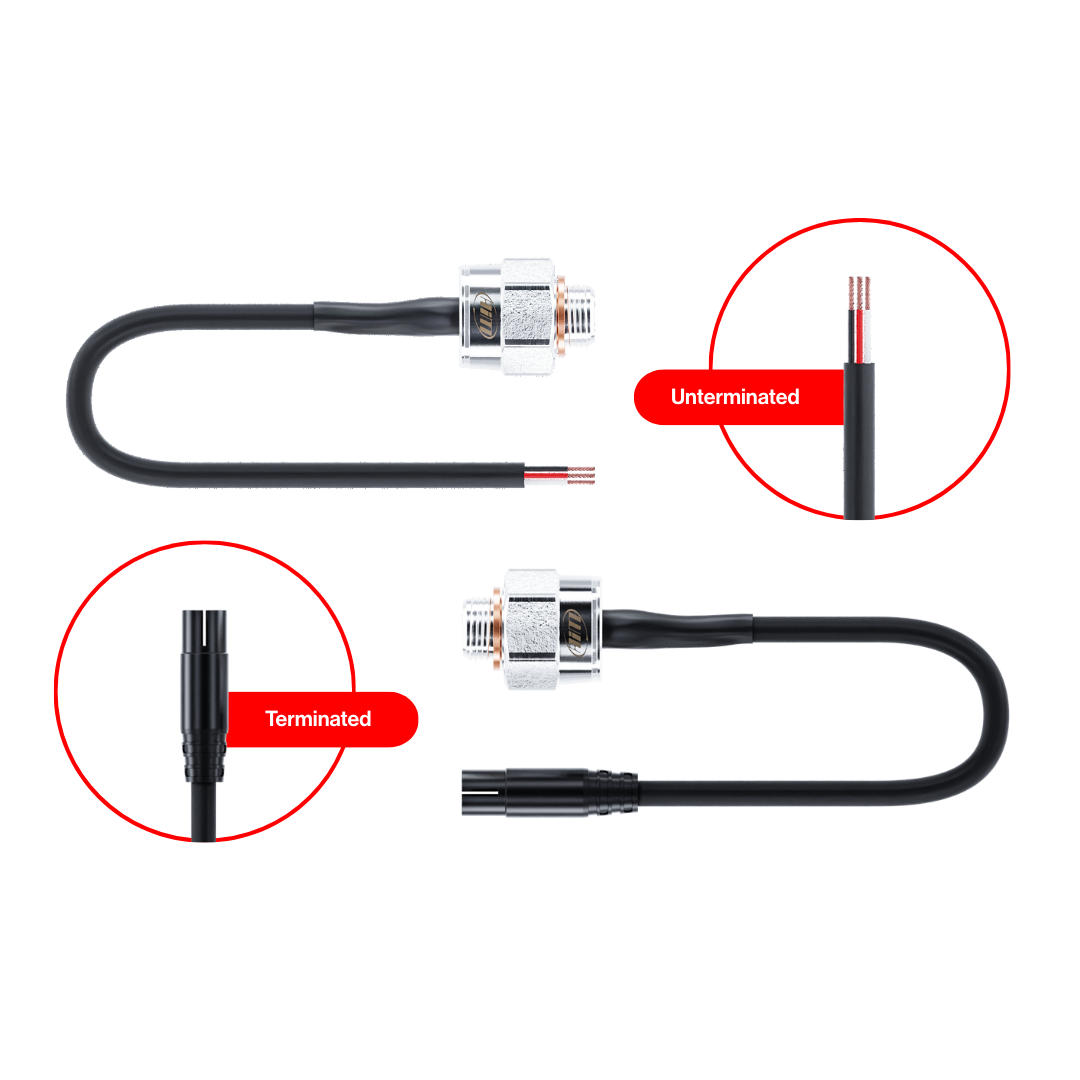

We also offer unterminated sensors that are designed to work seamlessly with Bosch, MoTeC, Cosworth, or other manufacturer hardware, making it easy for you to integrate the reliable and efficient Aim Pressure Sensors into any setup.

Expand Your System

You can expand your system with a range of products from the ACC3 Analogue CAN Converter, Displays and Loggers, Data Hubs and more.

To extend the length between a dash display/logger and an analogue pressure sensor, you will need a 719-719 patch lead, available in lengths between 0.5m and 4m.

Technical Information

Technical Specs

Diagram

Pinout

Included in the Box

Chosen 0-160 Bar Pressure Sensor

-

Free Aim Software